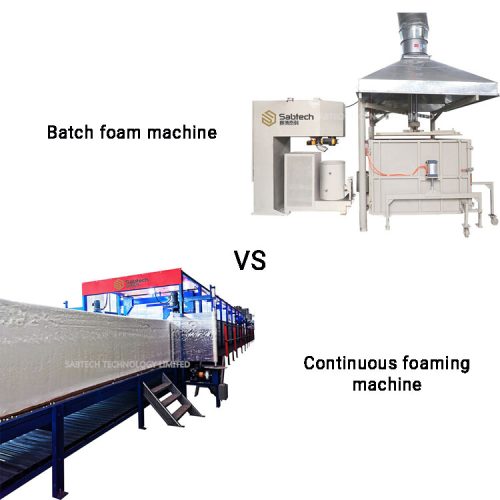

Polyurethane foam can be manufactured either in batch foam machine or in continuous foaming machine. However, their benefits are different:

Benefits of a Batch Foam Machine:

1.Precision: Batch foam machines are known for their precise mixing and dispensing, resulting in consistent foam quality.

2.Flexibility: Since batch foam machines can be adjusted based on specific product requirements, they are more flexible than continuous foaming machines.

3.Lower Cost: For smaller production runs, batch foam machines are typically cheaper than continuous foaming machines.

Benefits of Continuous Foaming Machine :

1.More Efficiency. Due to its substantially higher production rate compared to batch foam machines, continuous foaming machines produce foam at a far higher rate.

2.Scale: Continuous foaming machines are perfect for large-scale production runs since they consistently create high-quality foam with consistent qualities.

3.Automatic Operation: Continuous manufacturing is made possible by continuous foaming machines’ autonomous operation, which eliminates the need for frequent operator intervention.

4.Energy Efficient: Compared to batch foam machines, continuous foaming machines consume less energy per unit of output, which over time lowers their overall cost.

In conclusion, batch foam machines are more effective for precise foam mixing and dispensing, smaller production runs, and requirements for more complicated products. On the other hand, continuous foaming machines are perfect for extensive production runs, high output rates, and consistent foam quality.