How to increase the resilience of flexible polyurethane foam?

To increase the resilience of flexible polyurethane foam, you should focus on Cell Openness, Cell Geometry and Polyurethane Raw Materials.

To increase the resilience of flexible polyurethane foam, you should focus on Cell Openness, Cell Geometry and Polyurethane Raw Materials.

Polyurethane foam sponges are a variety of soft polyurethane foam plastics known for their porous honeycomb structure, which provides excellent softness, elasticity, water absorption, and water resistance. They find extensive use in industries like furniture, mattresses, clothing, and soft packaging.

The factors affect the quality and properties of rebonded foam are:

1.Foam Source and Composition

2.Shredding Method:

3.Additives and Bonding Agents

4.Temperature and Compression Pressure

5.Curing Conditions and Time

6.Techniques for Post-Processing

7.Quality Control Measures

Producing PU (Polyurethane) rebonded foam involves a similar process to general rebonded foam production, but with specific considerations for the polyurethane material. Here’s an outline of the process for producing PU rebonded foam and some best practices for achieving high-quality results:

Batch polyurethane foam machines need the proper safety measures and maintenance inspections because they are robust, sophisticated pieces of equipment. Performing in a safe and effective manner is ensured by doing this.

The mixing ratio is crucial to determining the effectiveness and quality of polyurethane foams produced by batch foaming machines.

Batch foam machines are perfect for mass manufacturing in the furniture and automotive sectors since they can manufacture massive amounts of foam.

It is well known that heat and pressure are crucial factors in the chemical reaction and physical traits of foam blocks that are produced by batch foam machines.

Polyurethane foam is used in a wide range of industries due to its versatility. As a machine to produce polyurethane foam, batch foam machine is widely used because of its flexibility and lower cost. Here are some tips for maximizing production efficiency with this equipment:

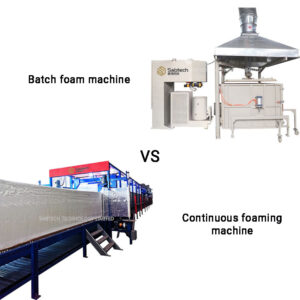

Polyurethane foam can be manufactured either in batch foam machine or in continuous foaming machine. However, their benefits are different:

We will contact you within 1 working day, please pay attention to the email with the suffix “@alforu.cn”.